Acrobat Printable Version

|

ELECT-19, Sensors and Gauges - Information, Troubleshooting, and Testing

|

There are two different styles of coolant temperature gauges used on 924s and 944s. The early style gauge was used on all models of 924s and on 944s up to the 1985 model year. The later gauge was installed on 1985.5 and newer 944s and 968s.

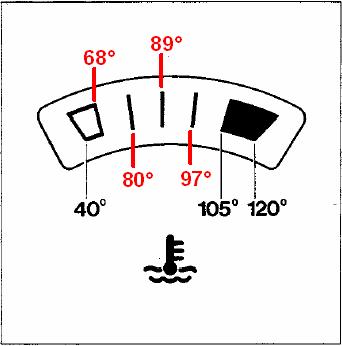

One of the difficult things about using a 924/944/968 coolant temperature gauge is that there are no real temperatures indicated on the gauge face. This can make it difficult to determine if the gauge, cooling system, or cooling fans are operating properly. It is therefore help to know what temperatures correspond to the markings on the gauge face. The diagrams below show those relationships. Temperatures are shown in degrees Celsius.

Many times I hear folks ask "what the normal coolant temperature for a 944?" Well, it's a difficult question to answer because there are a number of factors which can effect coolant temperature. However, generally speaking, in cool to moderate climates (up to about 25 °C) driving on the highway, 944 coolant temperatures will normally run between 80-90 °C. Under these conditions, the system typically runs cool enough that the radiator cooling fans will not run.

In warmer climates (25-35 °C) and in heavy traffic conditions with stop and go driving, coolant temperatures may run as high as 100 °C. The cooling fan(s) should come on at approximately 92 °C to reduce coolant temperature. If your coolant temperature consistently runs higher than 100 °C, it's time to start looking for problems. Realize that the problem could be an actual high temperature problem or it could be a problem with the temperature sensor or gauge.

Time and time again, I hear folks complaining about the car's coolant temperature running significantly higher than normal. When I start talking to them, I frequently find that these symptoms occur after a round of performance modifications where they've increased the horsepower the engine is making. What is frequently overlooked is that when an engine makes more horsepower, it makes more heat and more heat is rejected to the cooling system. Since nothing has been done to increase the capacity of the cooling system, with the increase heat load the steady-state cooling temperatures are naturally going to run higher than before. This means that the cooling fans will run more frequently, run longer, and have a harder time reducing/maintaining coolant temperature in hot weather and in stop and go driving. Realize also that this also means higher steady-state oil temperatures, lower oil viscosity, and hence lower than normal steady-state oil pressures.

|

|

|

|

|

| The numbers in red on the early gauge were determined by FR Wilk through interpolating the Bosch sender curves. | |

Testing Coolant Temperature Gauges

Tools

Procedure

Testing Oil Pressure Gauge

Problems with the oil pressure indication are commonly caused by a failing oil pressure sending unit. Normally, at startup when the ignition switch is turned on, the oil pressure will indicate 5 bar. Upon starting the engine the oil pressure should indicate between 4.5 - 5 bar. As the engine heats up the oil pressure will gradually decrease until the oil reaches normal operating temperature. At that point the oil pressure will normally indicate around 2.5 - 3 bar. On very hot days the oil pressure could indicate as low as 2 bar. If the indication falls below 2 bar and remains consistently below 2 bar, it could indicate a problem with the main or rod bearings.

Oil Pressure Gauge Testing

Testing Fuel Level Gauge

Testing and repair for the fuel level indication is covered in ELECT-18, Fuel Level Indication Problems / Repairs.

Air Flow Sensor (AFM) Testing

The Air Flow Meter (AFM) testing section has been move to a stand-alone procedure which is more accurate and now includes instructions for cleaning and repairing erratic operation. For AFM testing, refer to ELECT-22.

DME Temperature Sensor Testing

Tools

Procedure

The next part of the DME temperature sensor testing assumes that the temperature gauge on the dash is working properly.

Throttle Position Switch Testing

Throttle Position Switch testing is covered in FUEL-06, Throttle Position Switch Information, Troubleshooting, Replacement, and Adjustment.

Speed and Reference Sensor Testing

Speed and Reference sensor testing is covered in IGN-02, Checking, Replacement, and Adjustment.

At 86 °F approximately 1.46 k-ohms