* If you do not have a deep 15/16" or 24 mm socket, a shallow socket with a short extension (1-2") will work.

NOTE

When setting the engine to TDC on the compression stroke for cylinder #1, you must realize that the crankshaft rotates twice for every single rotation of the camshaft. So, if you simply set the crankshaft to TDC without looking at the position of the camshaft, you may actually be at TDC on the exhaust stroke for cylinder #1. So, after you get the crankshaft (by flywheel indication or by checking actual piston location), check the camshaft sprocket to make sure the camshaft alignment mark is at the TDC position as well.

- This procedure can be performed by one person. However, it is much easier to perform with two people.

- At the back of the engine compartment, looking from the left side of the car, locate the square opening (window) in the top of the clutch housing.

- You will be looking for the letters "OT" to appear in the opening as the engine is rotated.

Note: The crankshaft should not be rotated, manually or otherwise, unless the timing belt is installed with timing properly set or the camshaft housing assembly removed. This is done to prevent valve/piston damage.

- Using the 15/16" or 24 mm deep socket and ratchet, rotate the engine in the clockwise direction using the crankshaft pulley bolt on the front of the engine until the letters "OT" appear in the clutch housing window.

NOTE

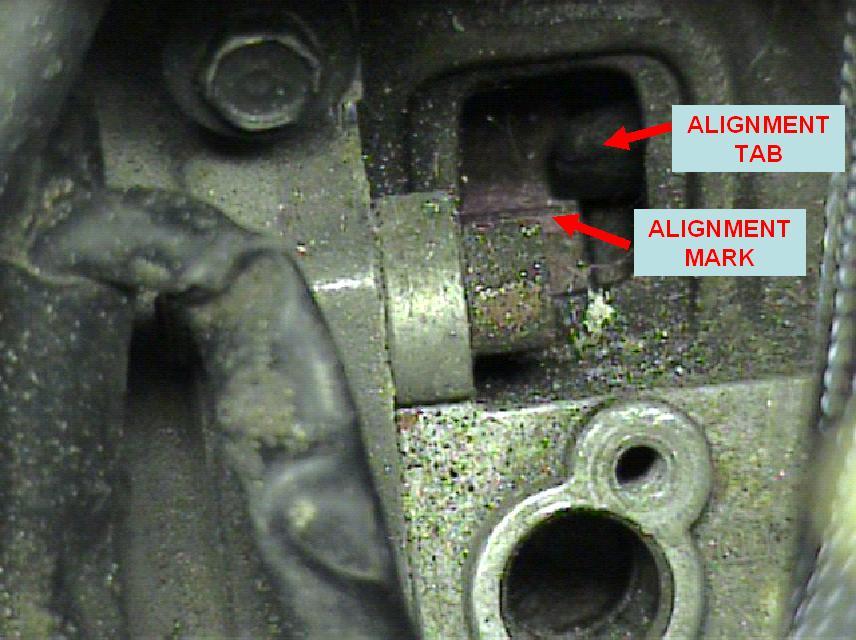

The picture below was taken on my own car. The "OT" is not really visible in the clutch housing opening due to the rust on my flywheel. However, some time ago, I painted the TDC line on my flywheel with red fingernail polish so it would be clearly visible. From the angle this picture is taken it appears that the alignment mark is slightly off from the alignment tab in clutch housing but it's simply due to the angle. To correctly align the mark for TDC you need to be looking directly down on the opening.

Many people have trouble locating the opening in the clutch housing for the TDC mark. You'll note in the picture the close proximity of the opening to the speed/reference sensor mounting bracket (sensors removed in this picture).

NOTE

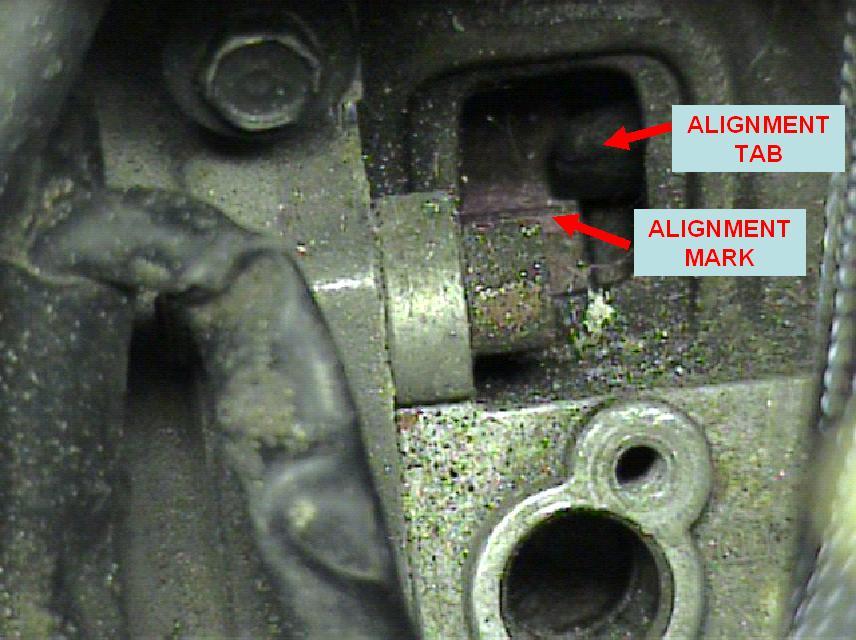

In the picture below, you'll see what the "OT" mark would look like on the flywheel if it is clean (unlike the previous picture).

Note: If this is being performed by one person, the alignment mark on the camshaft sprocket can be used to determine when the engine is close to Top Dead Center (TDC). However, the flywheel should be used for final alignment in case the timing is off slightly. The camshaft sprocket alignment mark is visible through the opening in the front distributor housing cover just above the distributor cap.

- When the letters "OT" are visible in the window, continue to rotate the engine clockwise until the scribe mark (line) beside the "OT" is aligned with the tab inside the window. The tab is on the side of the window closest to the middle of the car and extends down from the inside of the housing until it almost touches the flywheel.

- If you have trouble locating the TDC mark from above, there is a 5 mm wide groove in the flywheel which can be used to locate TDC as well. It will appear in an opening in the bottom of the clutch housing near the starter. When the groove is centered in the opening the #1 cylinder is at TDC. Personally, I don't care for this method because if the groove is not centered in the opening, the timing can be off ±

1 tooth.

- Alternatively, you can remove the #1 spark plug and insert a small diameter wooden dowel into the spark plug hole until it contacts the top of the piston. As the engine is rotated, the piston will force the dowel upward. When the end of the dowel is at its highest point, the engine is at TDC for the #1 cylinder.

- If the engine is not in the car and the clutch housing is removed, the "OT" scribe mark on the flywheel will line up with a cast mark on the back of the upper crankcase section when the #1 cylinder is at TDC.

- If the crankshaft pulley bolt needs to be removed or it is important that the engine remain at the TDC position, you'll need to install the "engine in" flywheel lock (9206). There is also an "engine out" flywheel lock (9130) which is used if the engine is on an engine stand. The engine out flywheel lock is not intended to maintain the engine at TDC but, is attached the flywheel to provide counter-torque against the engine stand arms for removing/installing the crankshaft pulley bolt or removing/installing the flywheel cheesehead bolts.